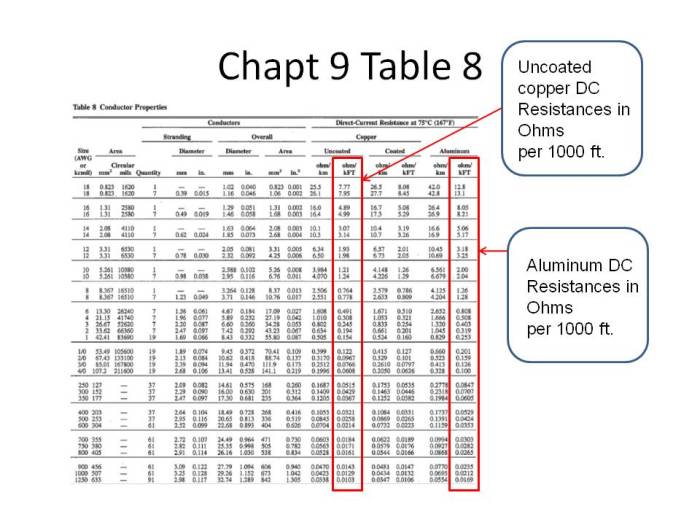

Chapter 9 Table 8 of the NEC is an essential resource for electrical professionals, providing critical information on conductor ampacity. Understanding this table is crucial for ensuring the safety and efficiency of electrical systems.

This table Artikels the ampacity values for various types of conductors under different environmental conditions. By leveraging this data, engineers can make informed decisions about electrical design, ensuring compliance with industry standards and maximizing system performance.

Chapter 9 Table 8 of the NEC

Chapter 9 Table 8 of the National Electrical Code (NEC) provides information on the ampacity of conductors. Ampacity refers to the maximum amount of current that a conductor can safely carry without overheating. This table is an essential reference for electrical professionals as it helps ensure the safe and efficient operation of electrical systems.

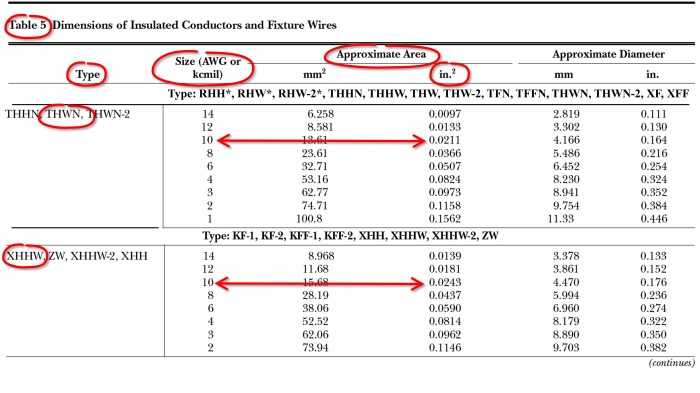

The table lists the ampacity of various types of conductors, including copper, aluminum, and steel. It also takes into account factors such as the conductor size, insulation type, and ambient temperature. By using this table, electricians can select conductors that are appropriately sized for the load they will be carrying, reducing the risk of electrical fires and other hazards.

Conductor Ampacity

Conductor ampacity is the maximum amount of current that a conductor can safely carry without overheating. It is determined by several factors, including the conductor material, size, insulation type, and ambient temperature.

Chapter 9 Table 8 of the NEC provides ampacity values for different types of conductors. These values are based on the assumption that the conductors are installed in free air at an ambient temperature of 30°C (86°F). If the conductors are installed in a conduit or other enclosure, the ampacity must be reduced.

Conductor Material

The conductor material is a major factor in determining ampacity. Copper has a higher ampacity than aluminum, and aluminum has a higher ampacity than steel. The table below shows the ampacity values for different conductor materials:

| Conductor Material | Ampacity (A) |

|---|---|

| Copper | 200 |

| Aluminum | 150 |

| Steel | 100 |

Environmental Conditions

The environmental conditions surrounding a conductor can significantly impact its ampacity. Chapter 9 Table 8 of the NEC considers various environmental factors that affect conductor performance.

One of the most influential factors is ambient temperature. As the temperature rises, the conductor’s resistance increases, leading to reduced current-carrying capacity. This is because higher temperatures cause the electrons in the conductor to move more rapidly, resulting in increased collisions and energy loss.

Conductor Grouping

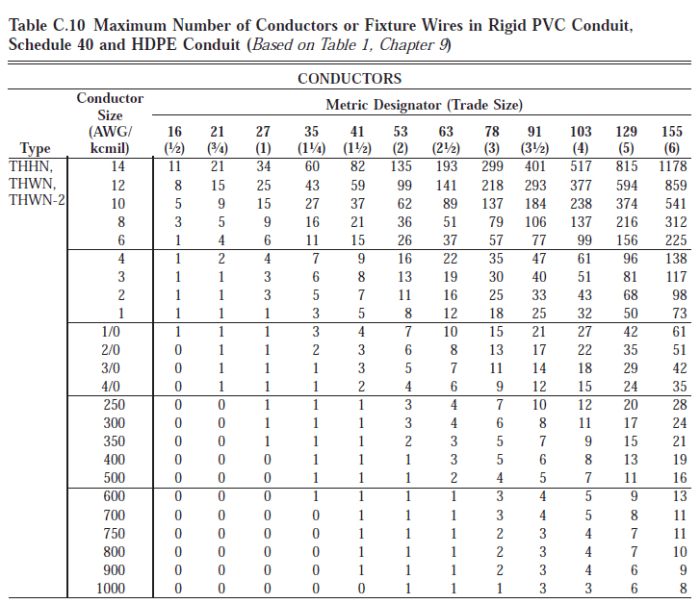

When conductors are bundled together in a conduit or cable, the heat generated by each conductor can accumulate, further reducing the overall ampacity. This effect is known as “conductor grouping” and is accounted for in Chapter 9 Table 8.

Another environmental factor that affects ampacity is sunlight. Direct sunlight can heat conductors, especially those exposed outdoors. This heating effect can reduce the conductor’s ampacity by up to 15%.

Application Notes: Chapter 9 Table 8 Of The Nec

Chapter 9 Table 8 of the NEC provides valuable guidance for selecting conductor ampacities based on environmental conditions. To ensure proper application, it’s crucial to consider the following application notes and special considerations:

Derating Factors, Chapter 9 table 8 of the nec

The ampacities listed in Chapter 9 Table 8 are based on specific environmental conditions. When these conditions vary, derating factors must be applied to adjust the ampacity. For instance, if the ambient temperature exceeds the assumed temperature in the table, the ampacity must be reduced to account for the increased heat.

Grouping of Conductors

When multiple conductors are bundled or grouped together, the ampacity is affected. The table provides correction factors to account for the reduced heat dissipation in grouped conductors. These factors ensure the conductors operate within safe temperature limits.

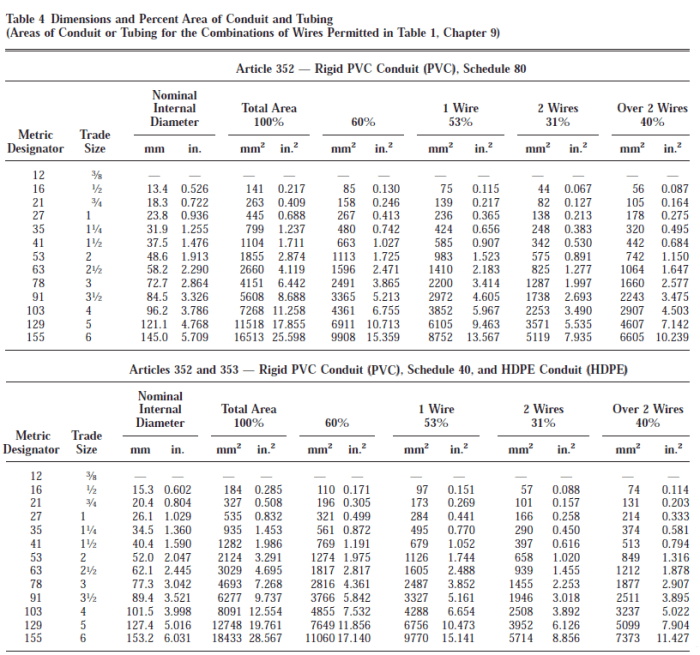

Enclosed Spaces

Conductors installed in enclosed spaces, such as conduits or cable trays, experience reduced heat dissipation. Chapter 9 Table 8 provides derating factors to adjust the ampacity for these scenarios, ensuring the conductors are protected from overheating.

Example

Consider a scenario where a three-phase, four-wire circuit with copper conductors is installed in a conduit in an ambient temperature of 40°C. The circuit operates at 100 amperes. Using Chapter 9 Table 8, we find the ampacity for three current-carrying conductors in a conduit at 40°C is 95 amperes.

Therefore, the derating factor is 95/100 = 0.95. The adjusted ampacity for the circuit is 100 x 0.95 = 95 amperes.

Comparison to Other Standards

Chapter 9 Table 8 of the NEC is a widely used reference for conductor ampacity and environmental conditions. It provides essential information for electrical engineers and designers to ensure the safe and efficient operation of electrical systems.

Similar tables can be found in other electrical standards, such as the International Electrotechnical Commission (IEC) 60364 series and the Canadian Electrical Code (CEC). These tables share some similarities in approach but also have some key differences.

IEC 60364

The IEC 60364 series of standards provides comprehensive guidance on the electrical installation of buildings. Table 52A of IEC 60364-5-52 provides conductor ampacity values for various types of conductors and environmental conditions. Similar to Chapter 9 Table 8 of the NEC, Table 52A considers factors such as conductor material, insulation type, and ambient temperature.

One key difference between Table 52A and Chapter 9 Table 8 is the treatment of correction factors for grouped conductors. IEC 60364-5-52 provides correction factors for up to 10 conductors in a bundle, while Chapter 9 Table 8 only considers correction factors for up to 3 conductors.

CEC

The CEC is the electrical code for Canada. Table 31 of the CEC provides conductor ampacity values for various types of conductors and environmental conditions. Similar to Chapter 9 Table 8 of the NEC, Table 31 considers factors such as conductor material, insulation type, and ambient temperature.

Chapter 9 Table 8 of the NEC outlines the requirements for electrical installations in hazardous locations. These locations are typically found in industrial settings where flammable gases, vapors, or dust are present. To ensure the safety of these areas, special precautions must be taken when installing electrical equipment.

The NEC provides detailed guidance on how to properly install and maintain electrical equipment in these hazardous locations, including the use of explosion-proof enclosures, proper grounding techniques, and the selection of appropriate wiring methods. For more information on how to safely install electrical equipment in hazardous locations, please refer to Chapter 9 Table 8 of the NEC or visit sweet chook o mine sandwich .

One key difference between Table 31 and Chapter 9 Table 8 is the treatment of ambient temperature. Chapter 9 Table 8 uses a fixed ambient temperature of 30°C (86°F), while Table 31 allows for adjustments based on the actual ambient temperature at the installation site.

Design Considerations

Chapter 9 Table 8 of the NEC provides essential information to guide electrical design decisions, ensuring the safety and efficiency of electrical systems.

By understanding the environmental conditions and application notes specified in the table, designers can select conductors with appropriate ampacity ratings to meet the specific requirements of their projects. This helps prevent overloading, overheating, and potential electrical hazards.

Conductor Selection

For instance, if an electrical system will be installed in a hot, humid environment, Table 8 indicates that the ampacity of conductors must be adjusted to account for the reduced cooling effect. This ensures that the conductors can safely carry the intended current without exceeding their temperature limits.

Circuit Protection

Additionally, the table provides guidance on the maximum allowable conductor temperatures for various types of insulation. This information is crucial for selecting appropriate circuit protection devices, such as fuses or circuit breakers, to prevent damage to the conductors and the equipment they supply.

Popular Questions

What is the purpose of Chapter 9 Table 8 of the NEC?

Chapter 9 Table 8 of the NEC provides ampacity values for different types of conductors under various environmental conditions, aiding in the design of safe and efficient electrical systems.

How does Chapter 9 Table 8 account for environmental factors?

Chapter 9 Table 8 considers environmental factors such as temperature, altitude, and conductor grouping, providing adjusted ampacity values to ensure proper operation under different conditions.

What are some application notes associated with using Chapter 9 Table 8?

Application notes for Chapter 9 Table 8 include guidelines for parallel conductors, derating factors, and conductor insulation types, ensuring accurate ampacity calculations.